Morgana ColorCut FB775

Description

Morgana ColorCut FB775 – Designed in the UK, beautifully engineered, totally accurate and highly affordable.

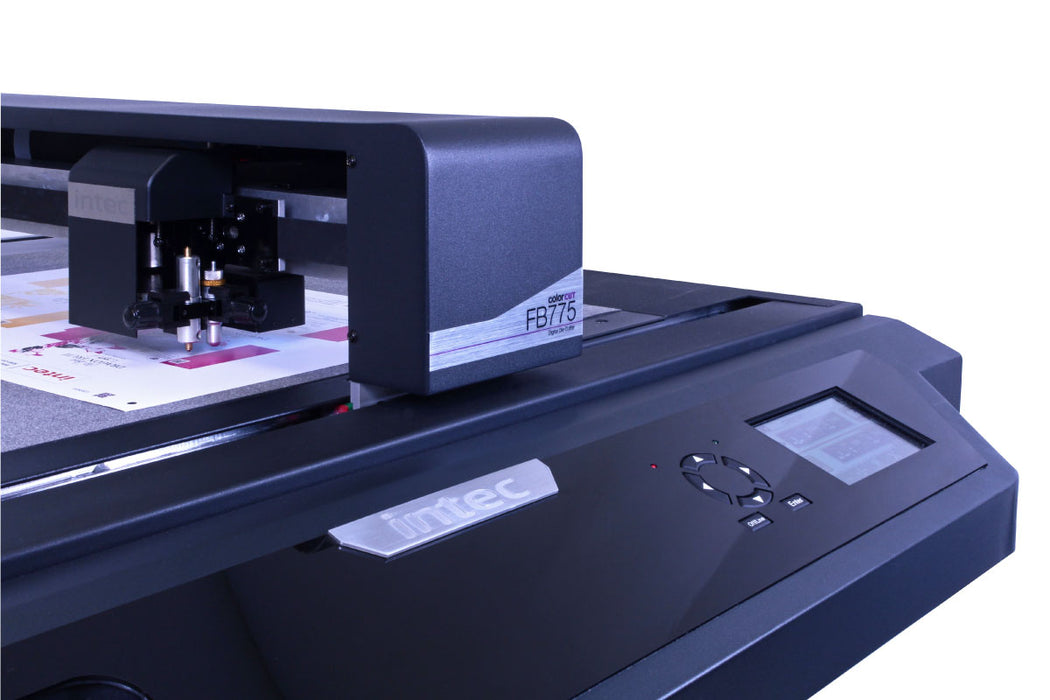

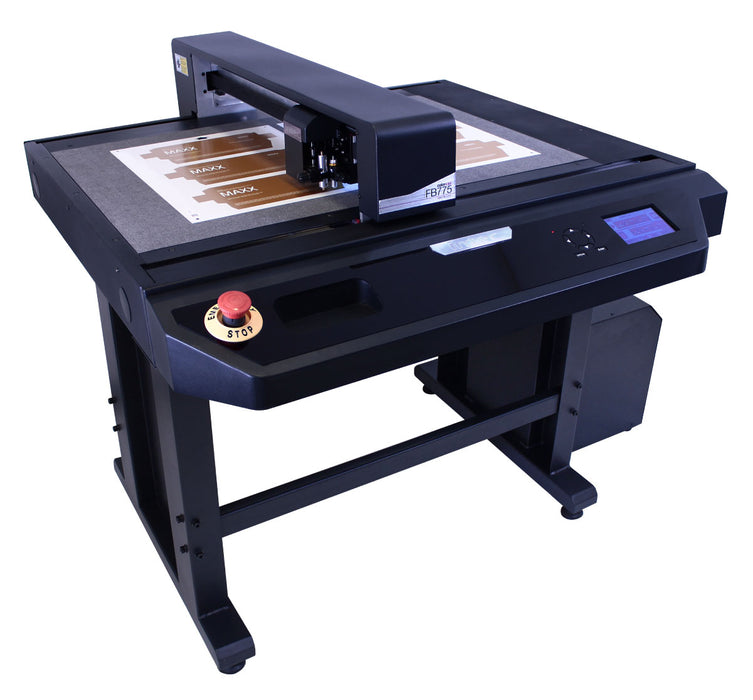

The Morgana ColorCut FB775 digital die flatbed cutter is a versatile and feature-rich mid-range model designed for large format sheet cutting, particularly for packaging, POS (Point of Sale), and labeling applications.

Key features:

B2+ Cutting Table: Designed for handling larger format sheets, making it suitable for various applications requiring significant cutting area.

QR Code Job Retrieval: A convenient and time saving feature that allows users to easily retrieve associated cut files by scanning QR codes. This can streamline the workflow and improve efficiency in job setup.

Registration Scanning System: The registration scanning system ensures precise and accurate cutting by aligning the cutter with the printed material. This is crucial for maintaining consistency and achieving high-quality results in packaging and labeling.

High-Speed Servo Motors: The advanced, high-speed servo motors contribute to the cutter’s speed and accuracy. This is essential for productive cutting, especially in applications where precision is critical.

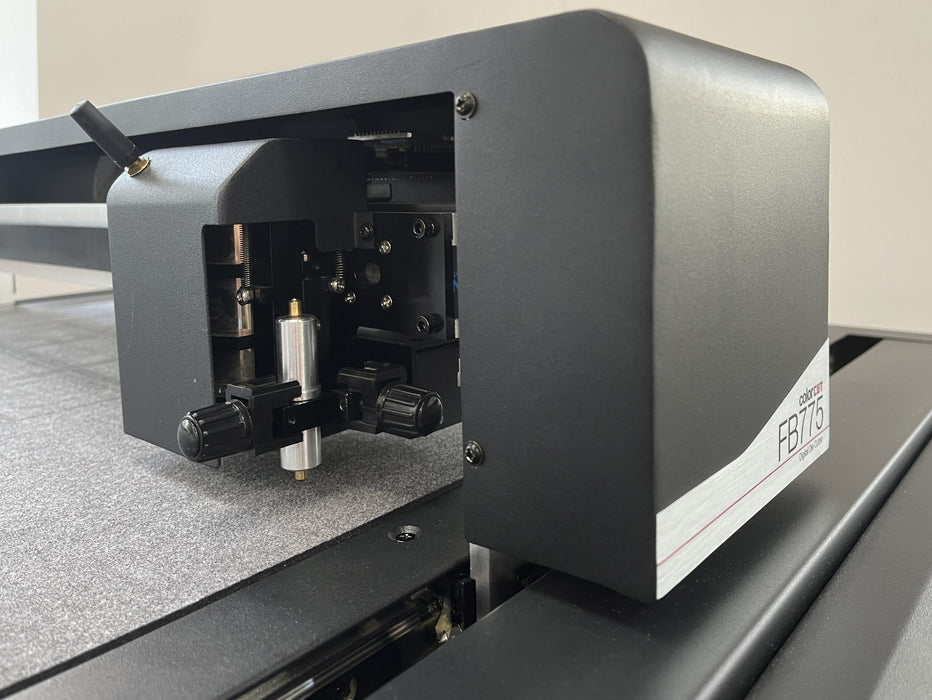

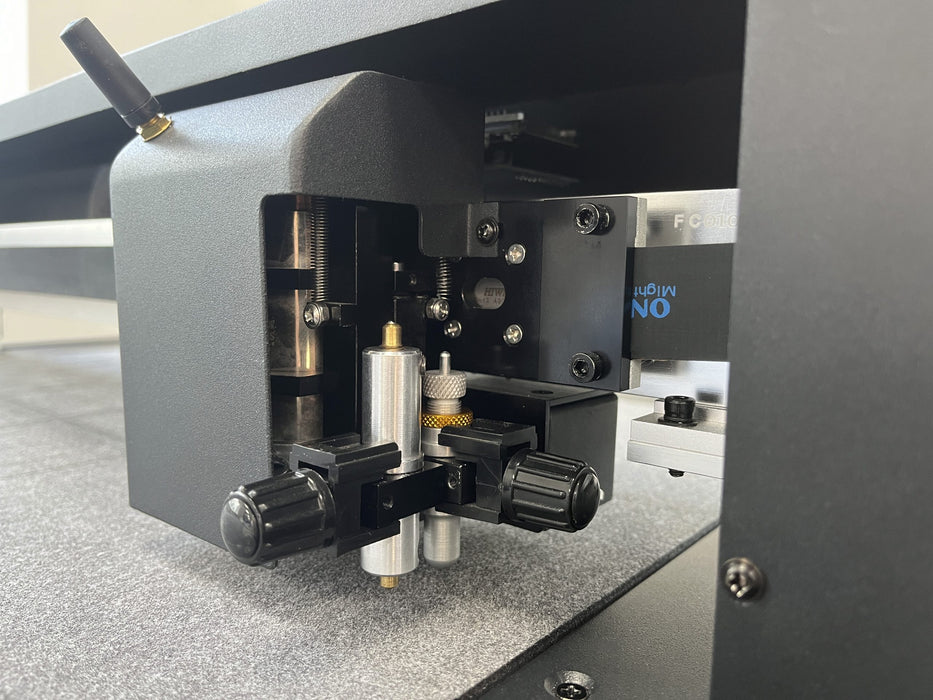

Dual-Tool Cutting Head: The enhanced dual-tool cutting head provides versatility by delivering high pressure for creasing (up to 1,500gf) and cutting (up to 1,200gf). This flexibility allows the cutter to handle a variety of materials and applications.

Cutting Capabilities: The cutter can cut through paper/card up to 1,000 micron (1mm), and able to handle a range of materials with different thicknesses and structure. This opens up new possibilities for diverse and creative applications.

Groundbreaking Design: The Morgana ColorCut FB775 incorporates innovative features or technology that sets it apart from other cutters in its class.

The Morgana ColorCut FB775 offers a combination of advanced features, precision, and versatility, making it well-suited for various cutting applications in the packaging and labeling industry.

Cartons, packaging, point of sale & kiss cut labels -all with one system!

Morgana ColorCut FB775

The flatbed come complete with a selection of cutting blades and mats to suit a wide range of materials being cut including lightweight papers, cards, label stock and synthetic substrates. Create stunning packaging with superb creasing and crisp cut lines/perforations on heavier-weight stocks for items such as luxury product packaging, gift boxes, utility packing and much more by using the supplied superior grey felt cutting mat and industrial circlip blades (included with every flatbed) making it suitable for use with heavier-weight materials. Perfect kiss-cut labels, interior and exterior point-of-sale, novelty greetings cards and vinyl decals can also be produced when used in conjunction with the provided self-healing cutting mat.

Engineered for reliability

Designed in the UK, the ColorCut flatbed range has a pedigree of solid engineering, robust mechanical parts, the latest high-tech electronics and simplicity of use – all at an extremely affordable price point! Digital die cutting. Using advanced digital contour cutting technology, the flatbed tools follow artwork. cut and crease lines drawn in Adobe Illustrator or CorelDRAW – no need to purchase and wait for traditional dies to be made.

Key Features

Deliver on demand

Cuts a typical SRA3 sheet in just 30 – 60 seconds. This enables users to easily and affordably produce anything from as little as one or as many as 1,000 sheets per day.

Vacuum hold down table

Sheets are held securely in place on either a green self-healing or superior grey felt cutting mat, by a vacuum produced by a powerful centrifugal air pump. Suction passes through the perforated hold down table and the mat, keeping sheets flat and secure.

Job sensing

Perfect registration of the printed sheets to the desired cut line is guaranteed by the presence of an optical sensor or CCD camera, which reads page marks and barcode/ QR code (see software section), and enables the dual tool head to follow the path of drawn vector lines.

Batch productivity

Multiple sheets can be placed on the cutting mat and with the control settings designated to ‘batch productivity’, ColorCut will proceed to work on each sheet in turn – thus speeding productivity even further!

Dual tool cutting head

Delivering at least twice the pressure of other models in its class, the ColorCut flatbeds use a dual tool head where both tools operate independently from each other, for all functions, reducing operation time and improving productivity. The creasing tool is double-ended, offering a choice of wide or narrow crease, as required.

Fingertip control

The intuitive touch screen control panel integrates with ColorCut Pro (see software section) and display’s easy to follow instructions, ensuring operators are able to respond effectively to system requirements.

High power vacuum included

All Intec ColorCut flatbeds come with an extremely powerful centrifugal air pump which provides the power, to hold down printed sheets, onto the cutting table. An auto cut-off feature announces the end of each cut sheet. The pump is housed within an attractive, purpose made acoustic housing and supplied with an effective silencer*.